The 30-Second Trick For Motorcycle Parts New Zealand Specialists

Motorcycle Parts New Zealand Specialists Can Be Fun For Everyone

Table of ContentsEverything about Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Things To Know Before You BuyFascination About Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Things To Know Before You Get ThisGet This Report on Motorcycle Parts New Zealand SpecialistsThe Only Guide to Motorcycle Parts New Zealand SpecialistsThe Best Guide To Motorcycle Parts New Zealand Specialists3 Simple Techniques For Motorcycle Parts New Zealand Specialists

Reach out to one of our professionals today.CNC machining innovation is promptly becoming the centerpiece of various manufacturing procedures around the globe as a straight result of its many benefits over various other approaches. Additionally, the sectors that manufacture motorbikes have actually gotten on board with this pattern. The most ingenious firms are currently creating their engine elements and wheels making use of machining methods originally created for motorcycle components.

You may be asking yourself why we make use of. Currently that we have your interest let us clarify the reasoning behind this contemporary development in the motorbike production sector.

Examine This Report on Motorcycle Parts New Zealand Specialists

In enhancement, you have full control over the look of the parts, also down to the min information. Sometimes, motorcyclists might determine to spruce up their trip by mounting aftermarket parts or modifying the bike's remodeling.

Getting My Motorcycle Parts New Zealand Specialists To Work

CNC machining may be utilized to make almost all of a bike's steel and plastic parts. To proceed, we'll discuss several machined components for motorbikes.

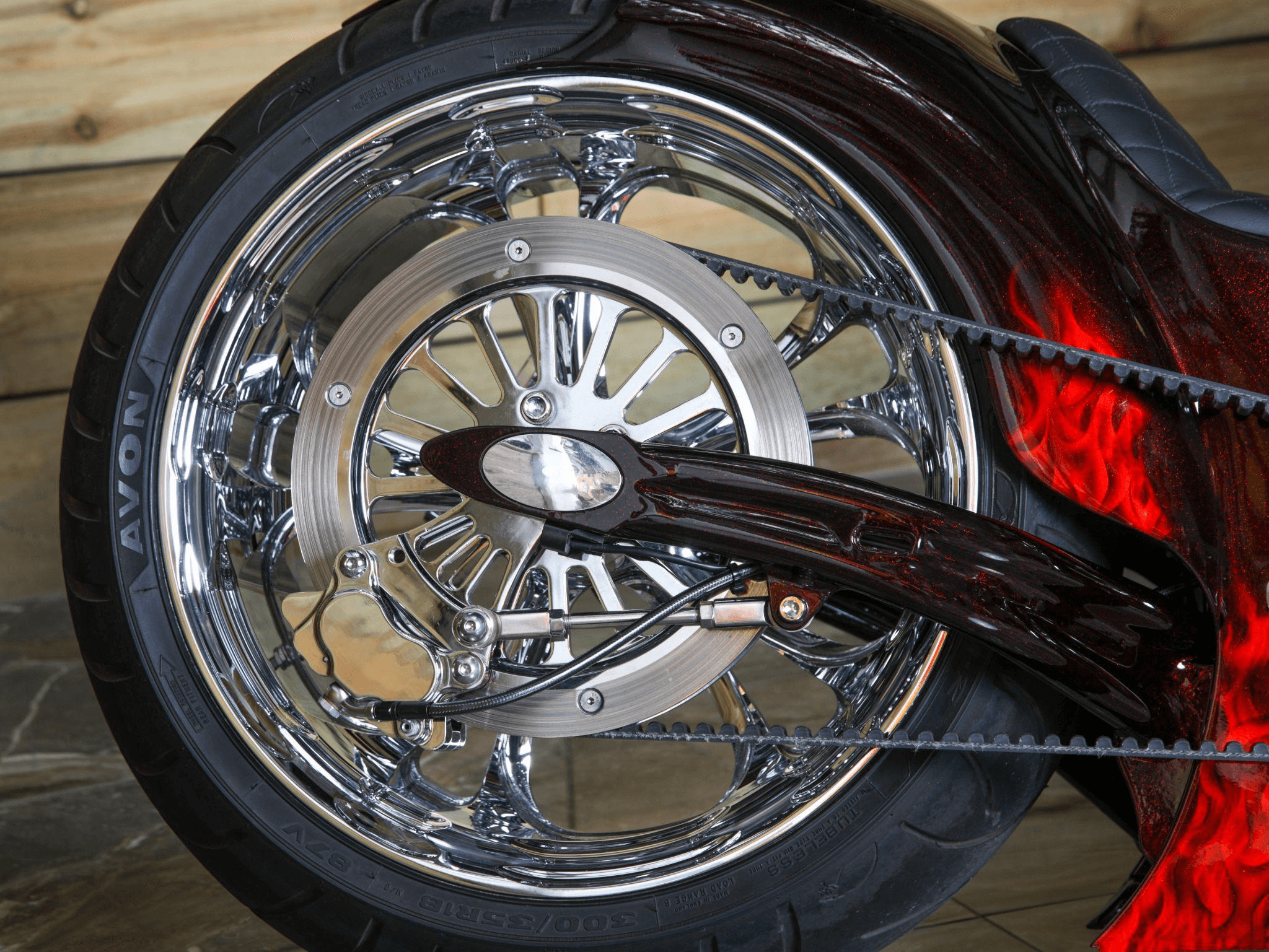

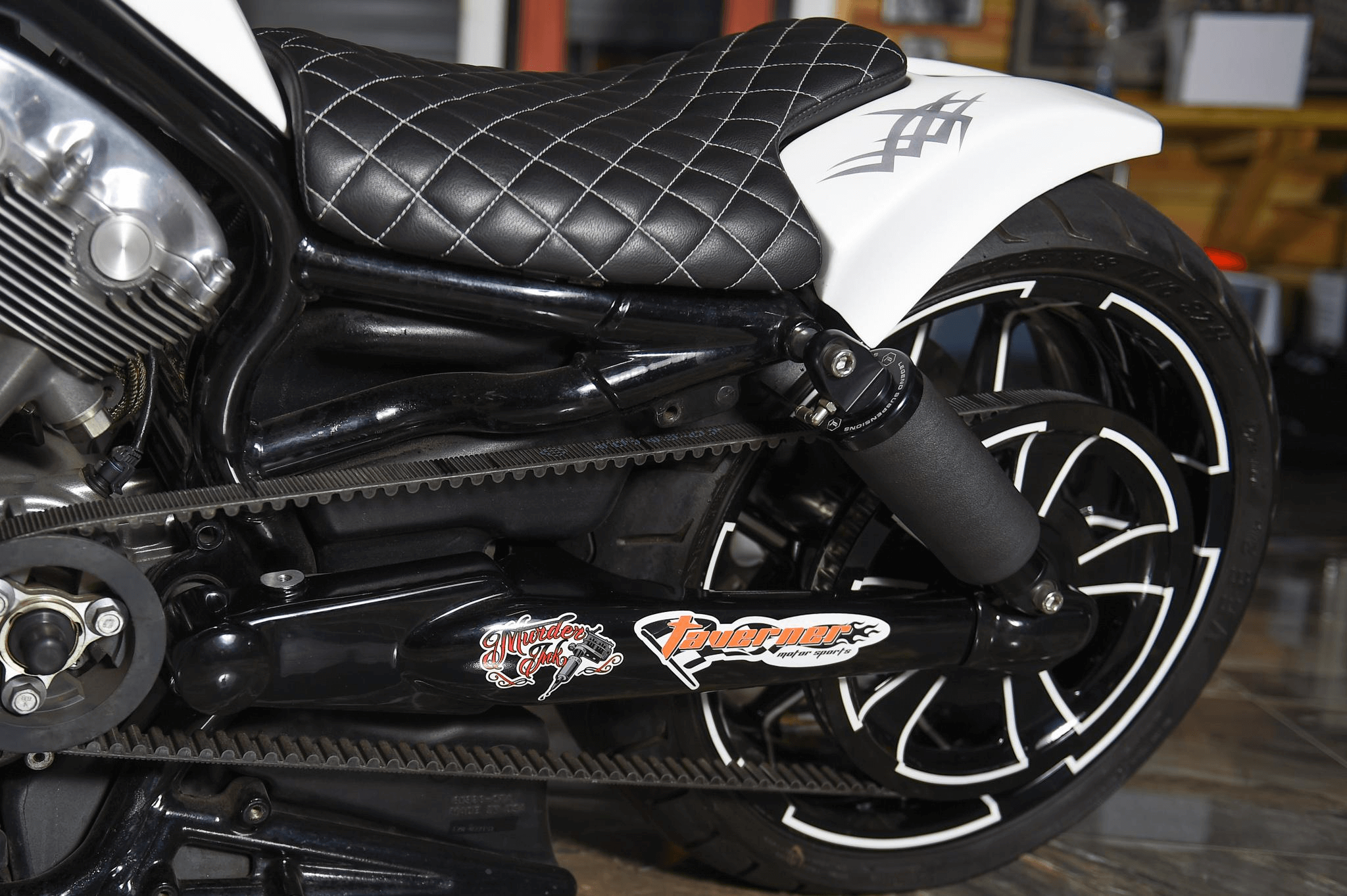

Milling procedures are made use of to get the wanted level of wheel personalization. Another element of the motorbike that may be customized is the tires.

Our Motorcycle Parts New Zealand Specialists PDFs

When it comes to a lorry (or a motorcycle), the most crucial element is the engine. Numerous individuals point to it as the "heart" of the vehicle. On the other hand, the camshaft, the cyndrical tube head, and the pistons have a tendency to be intricate and call for designs with a high degree of accuracy.

Usage only premium products, however, given that these lights are essential for the safety of motorcyclists and various other chauffeurs or people on the road, especially at night. Bike headlights have 3 primary parts: the bulb, or light resource, the lens, and the real estate.

Milling processes with a remarkable surface would lead to the lenses having a reflective high quality that is comparable to that of a mirror. The cover, on the various other hand, is not composed of vulnerable products; instead, it is built out of challenging polymers that can be machined right into more detailed patterns.

Getting The Motorcycle Parts New Zealand Specialists To Work

They commonly have intricate geometries with a wealth of minute information. Motorbike suppliers typically cast these components, however only for the production of bespoke parts. CNC machining is the technique of option when generating special pieces. Machining on 5 axes in today's globe is the ways through which any type of style shape may be understood.

The success of the procedure is contingent on the mill cutters' capability to calculate subtle and difficult angles accurately. Select Runsom for your tailored motorcycle parts! We have the capability to make challenging and stylish parts making your motorcycle unparalleled. Many are crafted from aluminum or steel alloys, each of which has its usages and advantages.

Below are a couple of examples of steels commonly made use of in motorcycle element machining. Aluminum is the primary product utilized by business specializing in generating personalized motorbike parts to develop most of these parts - Motorcycle Parts New Zealand Specialists.

Zinc describes an additional metal that is very light in weight and has excellent machining high qualities as a result of its high mechanical toughness. This product may be created into practically any shape and maintains its measurements well. Also mission-critical elements that need a high degree of precision may take advantage of their usage.

The Of Motorcycle Parts New Zealand Specialists

An additional steel that sees heavy use in the production of CNC-customized components is magnesium. It is among the lightest metals that are now easily accessible and has exceptional machinability attributes and toughness commensurate with its reduced weight. Among the drawbacks of magnesium is that its dirt may easily catch fire.

Due to its superior machinability and weldability, stainless steel is an alloy that is especially fit for CNC processes. They have great corrosion resistance and a high aesthetic allure. Their most common usage in creating different bike components is fasteners, such as screws and bolts. Their low sensitivity to oxidation and deterioration makes them ideal for this usage.

The Greatest Guide To Motorcycle Parts New Zealand Specialists

It appears that CNC turning and grating are the foundational procedures. Alternative methods exist, such as exploration. Allow's examine a number of these machining methods detailed. The CNC transforming technique is considered a subtractive manufacturing technique. Additionally, it needs keeping bars of product, usually plastic or steel, ready and after that twisting a reducing device to get rid of sections of the you can try here product as the product is transformed.

These methods are equally essential and produce components with high accuracy and constant top quality. They are specifically: grinding, laser cutting, and drilling. The term "surface area finish" refers to post-processes after the preliminary machining stage. Motorcycle Parts New Zealand Specialists. The processes help improve the total quality of the machined motorbike parts. Below are the brief introduction, advantages and disadvantages of 5 surface area therapy methods.

Getting The Motorcycle Parts New Zealand Specialists To Work